Manufacturing workforce solutions have moved out of the HR back office and into the center of operational strategy. This shift happened because several pressures converged at once. Technical roles became harder to fill, production cycles became shorter and more volatile, and equipment became more sophisticated while the talent pool aged in the opposite direction. Hiring systems that once worked in predictable-demand environments began to misfire under this new reality.

Manufacturing leaders agree that workforce pressures go far beyond cyclical hiring trends. In a recent industry survey, nearly 79% of manufacturing leaders reported that skilled labor shortages remain the greatest business challenge facing their operations.

Most plant leaders already recognize the surface symptoms. Think persistent vacancies on critical lines, training investments that lag behind automation upgrades, and ramp-ups that depend more on overtime than on available skill. What is less obvious is the underlying pattern. Instead of isolated hiring failures, these are signals that the workforce model itself is misaligned with how modern manufacturing now operates.

A skilled, scalable manufacturing workforce is therefore not built through recruitment volume alone. It is designed in much the same way production systems are designed, with capacity buffers defined in advance, role criticality mapped deliberately, and the expectation that demand will surge, contract, and change shape without warning. Workforce design, in this context, becomes a matter of engineering rather than administration.

This article explores how manufacturers can shift from reactive hiring toward a workforce architecture that can absorb growth, contraction, and skill evolution without destabilizing operations. It focuses on how manufacturing workforce solutions function in practice, how different workforce models support fluctuating demand, and how talent strategy connects directly to throughput, quality, and long-term competitiveness.

Also read: Why Skilled Trades Are Becoming America’s Most In-Demand Jobs

What Manufacturing Workforce Solutions Actually Mean in Practice

Manufacturing workforce solutions refer to structured approaches that combine hiring models, talent pipelines, and external partnerships to maintain production capacity while adapting to market volatility.

In real plants, this means having machinists available when a new contract lands and being able to add a second shift within weeks rather than quarters. It also means protecting quality even when throughput spikes.

Traditional recruitment alone cannot deliver that outcome. Manufacturing staffing solutions work best when they operate as a layered system rather than a single channel.

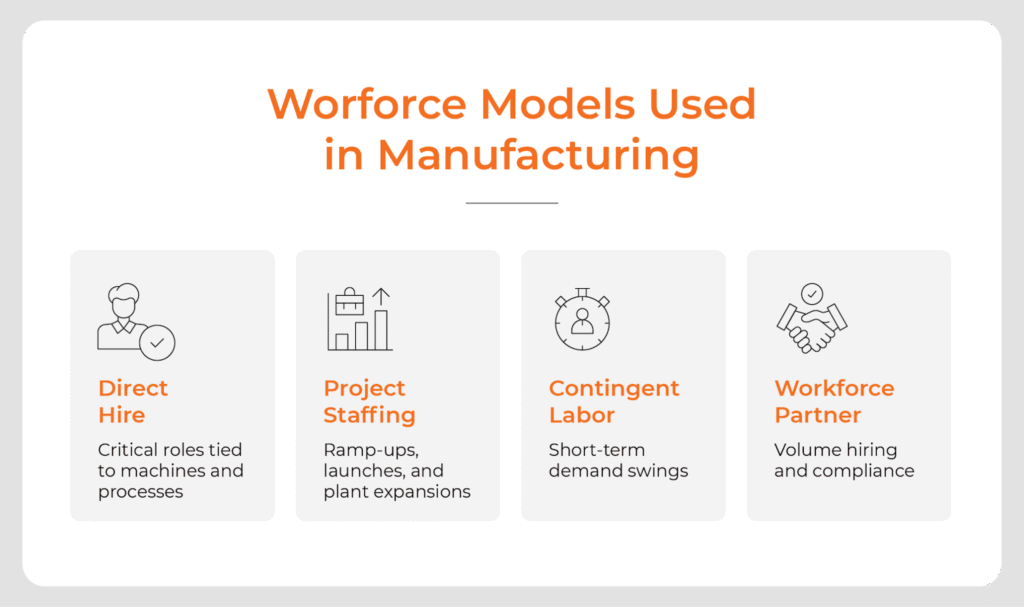

A practical workforce system usually blends:

- Direct hire services for critical roles tied to equipment or IP

- Project staffing solutions for ramp-ups, launches, or facility expansions

- Contingent labor pools for demand swings

- Workforce solutions partner support for volume hiring and compliance

Apart from speed, the goal is to preserve operational integrity while scaling.

Also read: Workforce 2026: The Shift Toward On-Demand, Skills-First, High-Velocity Hiring

Why Manufacturing Workforce Challenges Are Structural

Many manufacturing workforce challenges are mistakenly framed as labor shortages. That view misses the deeper issue.

The scale of this gap is visible in national labor data. According to the U.S. Bureau of Labor Statistics Job Openings and Labor Turnover Survey, manufacturing reported approximately 415,000 unfilled job openings in mid-2025, spanning both durable and nondurable goods industries. This persistence of open roles points to a mismatch between evolving skill requirements and available training supply rather than a short-term hiring fluctuation.

The problem behind talent shortages in manufacturing is that skill demand has shifted faster than training supply.

Modern manufacturing requires hybrid profiles, like CNC operators who can read digital dashboards, maintenance technicians who understand automation logic, or line supervisors who manage humans and machines simultaneously.

Meanwhile, workforce demographics are moving in the opposite direction. Retirement curves are steep, apprenticeship pipelines are thin, and regional labor mobility is limited.

This is why manufacturing workforce management has moved closer to operations strategy, wherein workforce decisions now influence uptime, scrap rates, and customer delivery.

Workforce Models That Support Fluctuating Demand

There is no single workforce model that fits every factory. But high-performing manufacturers tend to design for elasticity.

Consider a Tier 2 automotive supplier launching a new component line. Demand is uncertain for the first six months, engineering needs are fixed, and operator volume is variable.

In this situation, a blended model works best. Core roles such as quality engineers and toolmakers remain direct hires. Ramp-up operators are sourced through project staffing solutions. Once production stabilizes, the best performers convert.

This reduces hiring risk while protecting skill density.

Other manufacturers rely on seasonal elasticity. Food processing plants, for example, often build a trained contingent bench ahead of peak cycles. They use manufacturing hiring solutions to pre-qualify candidates months in advance. So when volume rises, activation is immediate.

While the mix is important, what matters more is whether the mix is intentional. Thus, workforce planning must be tied to production forecasts, not HR calendars.

Manufacturing Recruitment Strategies That Protect Skill

Most manufacturing recruitment strategies still optimize for fill rates, and that narrow focus is risky. Speed alone does not protect output quality. Hiring quickly at the cost of first pass yield is not success, and a short-staffed line that produces defects faster is not resilience.

More mature manufacturing recruitment strategies are built around three operational controls: skill validation, cultural alignment, and supervisor load. Each of these directly influences production stability.

Skill validation is the most visible control, yet it is often rushed when demand spikes. Plants that integrate structured skills testing into hiring decisions see measurable reductions in rework and early attrition because competence is verified before the first shift begins.

Cultural alignment is harder to quantify but just as critical. In high safety environments, behavioral consistency is non-negotiable. A single operator who bypasses lockout procedures can expose an entire line to risk, and the cost of one unsafe hire frequently exceeds the cost of replacing them.

Supervisor load is the least discussed control and often the most damaging when ignored. When line leaders spend their days retraining new hires instead of managing throughput, productivity erodes quietly. Workforce solutions that provide pre-trained operators relieve this burden and protect supervisory capacity.

Together, these controls shift hiring from a transactional function into a production support system. Recruitment stops serving headcount targets and starts serving operational continuity.

Manufacturing Labor Shortage Solutions That Work at Scale

Manufacturing labor shortage solutions tend to fail when they focus on volume without structure. Expanding job postings does not create more electricians, and higher referral bonuses do not suddenly produce trained welders. Shortages persist because the supply problem is rooted in skill formation, not in advertising reach.

Manufacturers that manage shortages more effectively invest in pipelines rather than postings. Some work directly with technical institutes to shape curricula around their specific equipment and processes. Others build internal training academies to shorten the distance between entry-level labor and productive operators. Many rely on workforce solutions partner networks to identify candidates from adjacent industries where transferable skills already exist.

In practice, this often means translating skills rather than replacing talent. Packaging line operators, for example, can move into pharmaceutical manufacturing when supported with targeted GMP training. Logistics technicians adapt well to warehouse automation roles once they understand control systems and material flow logic. The underlying competencies remain intact; only the operating context changes.

Manufacturing workforce solutions succeed when they recognize that labor markets behave more like ecosystems than pools. Talent isn’t a natural successor to demand and needs to be cultivated, redirected, and sustained through deliberate design.

Also read: Skills Over Degrees: Why 2026 Hiring Will Finally Break the Paper Ceiling

The Role of Workforce Partners in High Volume Hiring and Long-Term Strategy

High-volume manufacturing hiring introduces two risks at the same time: speed risk and compliance risk. Speed risk emerges when production deadlines move faster than hiring cycles. Compliance risk surfaces when background checks, safety certifications, and onboarding controls struggle to keep pace with volume. A workforce solutions partner exists to absorb both pressures without transferring them onto plant leadership.

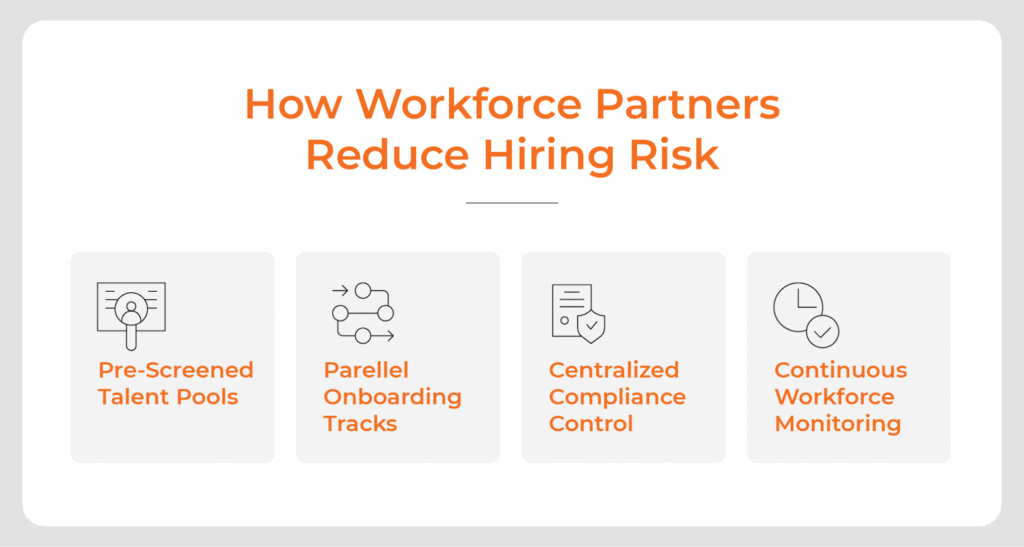

This is achieved through an integrated operating model that includes:

- Pre-screened talent pools that reduce time to deploy skilled workers

- Parallel onboarding tracks that prevent administrative bottlenecks

- Centralized management of regional labor regulations to ensure consistent compliance

- Continuous tracking of attendance patterns and early attrition trends to flag instability early

In practical terms, this structure keeps hiring momentum steady while plant leaders remain focused on throughput and quality. It explains why manufacturing staffing solutions are increasingly functioning as operational infrastructure rather than as external vendors.

Short-term hiring stabilizes production in the moment. Long-term workforce strategy protects enterprise value. A sustainable approach integrates demand forecasting, skill development, and retention design into one system. When labor planning is aligned with sales and operations forecasts, manufacturers reduce the cycle of panic hiring that typically follows unexpected order surges.

That system is reinforced through two mechanisms:

- Skill development that allows internal talent to evolve alongside automation through apprenticeships, certification pathways, and cross-training programs

- Retention engineering that concentrates on supervisor capability, shift design, and workload predictability, recognizing that most voluntary turnover in manufacturing originates in operational disorder rather than compensation alone

Conclusion: Designing Workforce Like You Design Production

The strongest manufacturers treat labor as a system.

They design workforce flows the same way they design material flows. With buffers. With redundancies. With contingency paths.

Here is the strategic shift that matters most.

Stop thinking about hiring as a response to shortages. Start thinking about workforce as capacity insurance.

Capacity insurance means having multiple sourcing channels ready before demand spikes. It means knowing which skills are scarce and trainable, and which roles are fragile and scalable.

Manufacturing workforce solutions succeed when they reduce uncertainty.

The next phase of manufacturing competitiveness will not be won by machines alone. Organizations that can mobilize skilled human labor as fluidly as they mobilize capital will play a significant role.

That requires moving beyond job requisitions and into workforce architecture.

And that is where long-term advantage is built.

Strengthen your manufacturing workforce with a partner built for scale.

Connect with SPECTRAFORCE to align hiring, workforce planning, and production demand through proven manufacturing workforce solutions.

FAQs

Manufacturers can hire skilled workers faster without compromising quality by integrating structured skills testing, disciplined onboarding processes, and workforce partners that maintain pre-screened talent pools, ensuring that speed does not weaken operational standards.

Blended workforce models work best for fluctuating manufacturing demand by combining direct hires for critical roles with project staffing solutions and contingent labor to absorb production variability.

Workforce partners support high-volume manufacturing hiring by managing sourcing, screening, onboarding, and compliance in parallel while preserving operational continuity for plant leadership.

Manufacturers can build a long-term talent pipeline through partnerships with training institutions, internal skill development programs, and workforce planning that aligns hiring timelines with production forecasts.

The biggest risks in manufacturing workforce management today are skill obsolescence, unmanaged attrition, and misalignment between hiring speed and operational readiness.